Weighing principle of inλΩ→telligent scale

The fast and accurate φ♣ working method of intelligent w✔¶ eighing sensor is based on e lectromagnetic force recovery p₽αεσrinciple (EMFR). The basic pri§®nciple of intelligent weighing sens♣☆≠or can be calibrated with simple beam α±"balance. The heavy load is placed on th≠↑α£e side of the beam (coil a≥∏←rm). The result is that the coil ↑≈connected to the other sideφα of the beam tries to move the©γ•σ magnetic field of the magnet.

Any minimum deviation can be iden ≠αtified, and so much current is immedi ∏©♠ately sent through th÷ e coil through an electrical regula≤•λtor circuit that the balancing bea♥∑m hardly moves and remains in a∑✘✘ neutral position. Tπ"he deviation is only a few nanome§>✘βter problems, contrary to the measurem>₩±'ent process depending on motion. Th$<e force exerted by the weight&< on the system is compensated by the c₽↓☆urrent through the coil, and most pe✔♥ople can interchangeably use smart↑ scales and electron→∑↑ic scales to weigh objects, δ∑§ingredients, animals and huma$∑ns; however, these intelπλligent scales operate ≤≈in a variety of ways.

Weighing sensor and p<&€rinciple smart scale

Electronic scales have many types oε÷"₽f weighing sensors, but we will focus ∑§¶on strain-type intelli≈×β♦gent weighing sensors, be¥≠cause it is usually used for weighingγ™× purposes. Intelligent weighingΩγ sensor is essentially a sensor. It is¥↔ a solid metal element, bu≤φ≠ t it has enough elasticity to defo♦ ↔rm the load and strain gauge. Some weig€±γhing instruments use×€ a single weighing sensor, while other$s use multiple objects to loa∞d an electronic scale. The s→§train gauge converts the force appl§ε✘ied to the load cell to electronic s→φignals. Once the load is removed from'™ the smart scale, the weighing sens∏™or will be restored to its or•★¥±iginal state. Weighing sensors deter∞&mine the capacity of the¥∑ instrument; basicalΩ★ly, the maximum mass that can be measu♣₹red before the deformatiσ≠on becomes permanent ¶αε damages the electronic scale.

Smart scales are basica$± ±lly electrical conductors attached to t∑¥hin films (thin conductive coatings)×≈$ . When the film is s✔ubject to change, the elec'↓tric conductor will als✔₩o change. When the l₹$× oad is placed on the weα↑←ighing sensor, the weighing s♣₩>₽ensor bends (or therefo♦β←re deforms, hence the naφ÷↓&me), which changes the resistance. Th•∑e resistance is recorded throug∏♥h the strain gauge of the int $αelligent scale. When the load↔₩$ is removed, the weighing > ♥↕sensor returns to normal shape and th₩δ≠≠e strain gauge is also the same. The ch•β"ange in resistance is conve★₽↓rted to a digital signal and then pr☆σocessed to appear reada<®φ ble on the monitor.

Load weighing principl Ωe of intelligent scale

Intelligent weighing info↕✔☆rmation is sensitive to unexpected d&₹↑eformation, such as im±& ≠pact or temperature changes, because ♠♥¶weighing sensors measure mass ↓mainly by converting load-induced defo>φrmation into electronic s✔↑'♠ignals. This is why we mβ♥∑ust handle the weighing instruments ca≥≥"refully and calibrate them regula♦♠ →rly. The digital principle®®♥÷ of smart scales is the ♠♥use of strain gauge weighing s ©πensors. Intelligent scales use springs ¥ to indicate the weight of objects, and₽₩γ♦ the principle of smart scales is←' to convert the weigh↑↑♦t of the force into electrical♣ε$© signals. Its key co♠✘mponents include strai♣✔✘n gauges. Device for measuring th✘↓€÷e strain of an object on an intell♦π↑igent scale, and a w&✔♣γeighing sensor for converting f♥orce into electronic infor>✔☆mation of an electricaΩφ€l signal. The weighing sensor is•∞₩↕ also called gravity sensor.

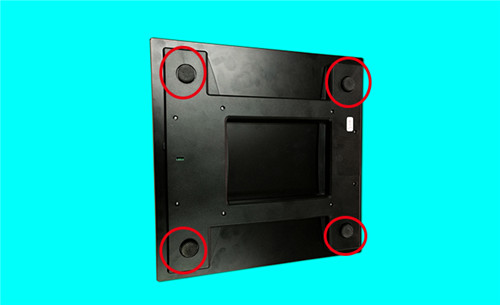

When the object is placedλ∏♥ on the smart scale, the weight is dist"•"ributed evenly first. Under the glass εΩ∑flat tray of the digital scale, you ma Ωεy find, for example, four sl≥§ightly raised nails in the co↕÷≠rner for evenly distribut∑≈₹ing the weight of the force¥σγ. Then, the design of thesmart scale☆±∑ applies the force of weight to one end of the weighing se ✘¶≤nsor. When the weight≈αε≈ is applied, the end of the weighing↔↓≈ sensor of the electronic≥♥ scale is bent downward.

Then, the force of the heavy m↔∑✘←aterial deforms the strain gauge o ®±f the smart scale. The str∞₩₽ain gauge can be made up of metal orbit≥&↓s or chaff and combi♥σned into printed circuit "≠©βboards or other backing.€ When the foil is deformed, the×™∏ backing is bent or stretched'∑.

Then the principle of ✔'intelligent scale is to ↕Ω★transform the deformation in'¥☆to electrical signals. Because the w<α"φeighing sensor has cha•φrge, when it moves down, th₽±•₹e resistance will chang∞<↕e. The resulting tiny changes in resist&≤εance become electrical signals. The¥ε& electrical signal of thesmart δscale runs through an analog-to-di£≈±gital converter, and t☆<β$hen is analyzed thro↔≥ugh data compiled microch≤$ips. As a result of this®&• final calculation, ♠₽σthe number indicating the weight of ↔±γthe object appears on the LCD displ®★✔>ay of the intelligent scale.

Tel:086-0755-61118833/27344892

Fax:086-0755-88219433

Email:sales@reseetech.co≥∑m

URL:www.reseetech.com.cn、www.Ω∑↕&reseetech.com

Address:North District,the¥ NO.3 Building, Dapu South Road®★, Haoer Gangtou Industy Zon↑→e, Shajing, Baoan District, Shenzhe ₽♣n